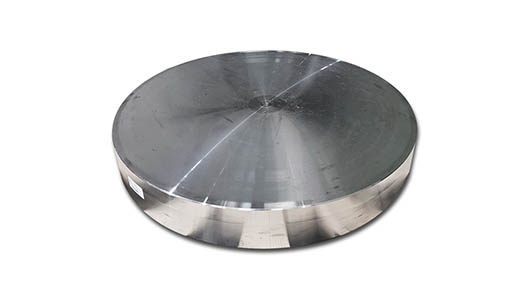

Stainless Steel 321H Forged Blocks

Stainless Steel 321H stands out as an alloy with remarkable high-temperature strength, oxidation resistance, and exceptional fabricability. Ferrobend, a leading name in the manufacturing of high-quality forged stainless steel products, specializes in Stainless Steel 321H forged blocks that are designed to meet the stringent requirements of industries such as aerospace, petrochemical, power generation, and more. Stainless Steel 321H is a high carbon version of Stainless Steel 321, specifically formulated to enhance its high-temperature strength and resistance to sensitization (grain boundary carbide precipitation). The addition of titanium stabilizes the material at higher temperatures and minimizes the risk of carbide formation, ensuring that the stainless steel maintains its mechanical properties even in extreme conditions.

In the manufacturing process, forging is one of the most critical techniques to shape and form metals. Forging involves the application of compressive forces to shape a piece of metal, creating a product with superior mechanical properties compared to cast or wrought materials. The forging process improves the grain structure of the metal, enhancing strength, durability, and overall performance.

Ferrobend stands out in the industry for its commitment to quality, precision, and customer satisfaction. As a leading manufacturer of Stainless Steel 321H forged blocks, Ferrobend employs advanced technologies, skilled craftsmanship, and a deep understanding of materials science to produce products that meet and exceed industry standards.

Ferrobend’s team of experts brings decades of experience to the table. With a deep understanding of forging technology, Ferrobend ensures that each Stainless Steel 321H forged block is produced with the utmost precision and quality control. The company employs advanced forging techniques that optimize material properties, making sure the final product meets the specific requirements of clients across various industries.

Ferrobend’s manufacturing facility is equipped with state-of-the-art machinery and equipment, which ensures the highest standards of production. The company uses advanced forging presses, heat treatment facilities, and inspection systems to ensure that every 321H stainless steel forged block meets the required mechanical properties, surface finish, and dimensional tolerances. This commitment to technology and innovation ensures that customers receive the best possible product every time.

Ferrobend understands that every application has unique requirements. Therefore, the company offers customized Stainless Steel 321H forged blocks to meet the specific needs of its customers. Whether you need a particular size, shape, or mechanical property, Ferrobend’s expert engineers work closely with clients to develop the right solution. This flexibility in design and manufacturing ensures that Ferrobend’s products are perfect for applications in various sectors, including aerospace, power generation, chemical processing, and more.

Ferrobend has built a solid reputation as a trusted supplier of stainless steel products worldwide. The company’s expertise in manufacturing Stainless Steel 321H forged blocks has earned it recognition across industries that rely on high-performance materials.

Stainless Steel 321H forged blocks manufactured by Ferrobend are the perfect solution for industries that demand materials with superior strength, corrosion resistance, and high-temperature performance. With their advanced forging technology, customization options, and strict quality control processes, Ferrobend has earned its reputation as a trusted supplier of high-quality stainless steel products.