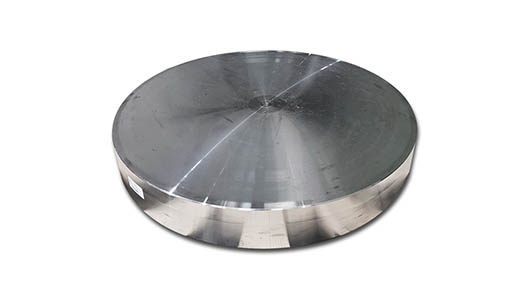

Stainless Steel 321H Forged Discs

Stainless steel 321H forged discs are highly sought after for their durability, resistance to high temperatures, and outstanding performance in harsh environments. At Ferrobend, we specialize in manufacturing these precision-engineered products using advanced forging processes and cutting-edge technology to meet the most stringent industry standards. This article will explore the benefits, manufacturing process, and applications of 321H stainless steel forged discs and why Ferrobend stands out as the premier choice for clients seeking premium-quality forged stainless steel products. Stainless steel 321H is a high-carbon version of the standard 321 stainless steel. It is specifically engineered to withstand elevated temperatures and offer exceptional resistance to oxidation and corrosion. The alloy is known for its enhanced strength, thermal stability, and weldability, making it an ideal choice for applications that involve exposure to high heat and corrosive environments.

The "H" in 321H signifies a higher carbon content, which further enhances the material's strength at elevated temperatures. At Ferrobend, we employ a precise and well-controlled forging process to manufacture 321H stainless steel forged discs. Forging is a highly effective method for producing durable and strong components. The process involves shaping the stainless steel by applying compressive force to the material, resulting in a refined grain structure that enhances its mechanical properties. The first step in manufacturing 321H stainless steel forged discs is the selection of raw materials. We source high-quality 321H stainless steel ingots from reputable suppliers, ensuring that the material meets all the required specifications for strength, corrosion resistance, and temperature tolerance.

At Ferrobend, we place great emphasis on quality control. Each stainless steel 321H forged disc undergoes rigorous testing to ensure it meets the highest industry standards. We perform a range of tests, including tensile strength, hardness, and corrosion resistance testing, to confirm that the discs perform as expected in their intended applications. We also conduct non-destructive testing (NDT), such as ultrasonic testing, to detect any internal flaws that could compromise the integrity of the discs.

After forging, the stainless steel 321H discs undergo heat treatment processes, such as annealing or solution annealing. This treatment is crucial for relieving stresses and improving the material's mechanical properties, such as toughness and resistance to corrosion. Our heat treatment processes are carried out in controlled environments, ensuring consistency and precision in the final product.

Ferrobend’s stainless steel 321H forged discs are engineered to perform in the most demanding applications, offering exceptional strength, corrosion resistance, and high-temperature tolerance. Our advanced forging processes, combined with rigorous quality control measures, ensure that each disc meets the highest industry standards. Whether you are in aerospace, chemical processing, or power generation, Ferrobend provides the reliability and precision you need for your forged stainless steel components.