Stainless Steel 321H Forged Flanges

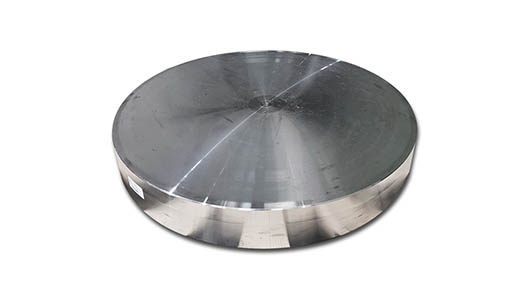

Stainless Steel 321H stands out as a popular choice for environments that demand exceptional high-temperature resistance and superior mechanical properties. For industries like aerospace, power generation, chemical processing, and petrochemicals, the integrity and reliability of components like forged flanges are non-negotiable. Ferrobend is a leading manufacturer of Stainless Steel 321H forged flanges, specializing in providing high-quality products tailored to meet the stringent requirements of industries worldwide. Flanges are mechanical components used to connect pipes, valves, pumps, and other equipment in piping systems. Forged flanges, specifically, are produced through a process in which the stainless steel material is heated and then shaped under high pressure to achieve superior strength, durability, and structural integrity.

Stainless Steel 321H is a high-carbon version of Grade 321 stainless steel, alloyed with titanium to enhance its resistance to oxidation and scaling at elevated temperatures. This alloy is ideal for applications that involve heat exposure, where conventional stainless steel might fail to perform. Stainless Steel 321H forged flanges are designed to provide an optimal solution for systems operating under high temperatures and aggressive chemical environments. Ferrobend’s forged flanges are manufactured to the highest industry standards to ensure that they offer both long-term performance and safety in the most challenging conditions.

Grade 321H has excellent resistance to a wide range of corrosive environments. The presence of titanium in the alloy helps stabilize the carbon content, which reduces the risk of carbide precipitation and intergranular corrosion. As a result, Stainless Steel 321H is highly resistant to both general and localized corrosion. Due to the forging process, the Stainless Steel 321H forged flanges produced by Ferrobend are highly resistant to mechanical stress and wear. Forging enhances the material’s tensile strength, providing greater durability in high-pressure applications, where welded flanges may fall short.

Stainless Steel 321H offers excellent weldability without the formation of carbide precipitation at grain boundaries, a problem often encountered with other stainless steel alloys during welding. This characteristic is essential for industries that require precise welding for flange joints and other piping connections. Ferrobend ensures that only the highest-grade Stainless Steel 321H billets are sourced from trusted suppliers. The material undergoes rigorous inspection and testing to confirm its compliance with industry standards and specifications before being used for forging. The billets are then heated to the required forging temperature to make them malleable. This process is carefully monitored to ensure that the material is uniformly heated. Once the billet reaches the desired temperature, it is placed into a die and shaped using high-pressure forging techniques. This process compacts the material and removes internal voids, resulting in flanges with enhanced strength and uniformity.