Stainless Steel 321H Forged Valves

At Ferrobend, we specialize in the manufacturing of Stainless Steel 321H Forged Valves, offering customers a combination of cutting-edge technology, expert craftsmanship, and unrivaled performance. Our valves are designed to meet the most stringent industry standards, making them the perfect choice for high-temperature and corrosive environments.Stainless Steel 321H is an enhanced version of 321 stainless steel, primarily known for its superior resistance to high temperatures and oxidative environments. Stainless Steel 321H contains a higher carbon content compared to regular 321 steel, which improves its strength at elevated temperatures. It is also stabilized with titanium, reducing the risk of carbide precipitation during welding, making it ideal for high-temperature applications such as in the aerospace, chemical, and petrochemical industries. The alloy’s properties of high-temperature stability, good oxidation resistance, and exceptional strength make Stainless Steel 321H the material of choice for producing forged valves.

These valves provide enhanced durability, reliability, and longevity in demanding service conditions. When combined with Ferrobend's state-of-the-art forging techniques, Stainless Steel 321H valves outperform others in terms of strength, resistance to corrosion, and resistance to thermal fatigue.

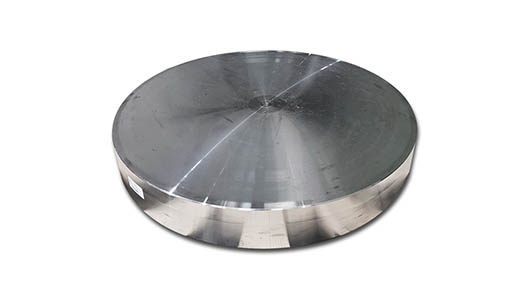

Forged valves are crafted through a process that involves shaping the material under high pressure and temperature, resulting in a denser and stronger product. This process ensures that the final valve is far more durable and resistant to stress and fatigue than valves made from cast or machined materials. Forged valves have superior structural integrity and can withstand much higher pressure and temperature fluctuations, making them ideal for critical applications in industries like oil and gas, power generation, petrochemicals, and pharmaceuticals.

Ferrobend has established itself as a leading name in the manufacturing of Stainless Steel 321H Forged Valves. Our commitment to quality and excellence is reflected in every aspect of our production process. We adhere to stringent quality control measures to ensure that every valve meets or exceeds industry standards, such as ISO 9001:2015, ASTM, and ASME specifications. Our advanced forging technology allows us to create valves with perfect precision, ensuring they perform flawlessly under high-stress conditions.

Ferrobend’s expertise in forging means that each Stainless Steel 321H valve is produced with unmatched accuracy. Our advanced forging processes ensure that every valve features precise dimensions, uniform strength, and minimal defects. We understand that every application is unique, which is why we offer customizable solutions for Stainless Steel 321H forged valves. Whether you need specific pressure ratings, sizes, or configurations, Ferrobend can produce valves that perfectly match your operational requirements.