Stainless Steel 321H Perforated Sheets-Plates

Stainless steel 321H perforated sheets and plates are an essential material used in various industries where durability, high-temperature resistance, and excellent corrosion resistance are required. Known for its superior strength and reliability, Stainless Steel 321H is a high-carbon version of Stainless Steel 321, which enhances its performance at elevated temperatures. At Ferrobend, we specialize in the manufacturing of high-quality Stainless Steel 321H perforated sheets and plates, designed to meet the diverse needs of industries like chemical processing, aerospace, and automotive. Stainless Steel 321H is a heat-resistant alloy designed for use in environments where high temperatures and corrosive substances are present. It is primarily used in high-heat applications, thanks to its outstanding resistance to oxidation and scaling. Stainless Steel 321H has excellent formability and weldability, which is crucial in various manufacturing processes.

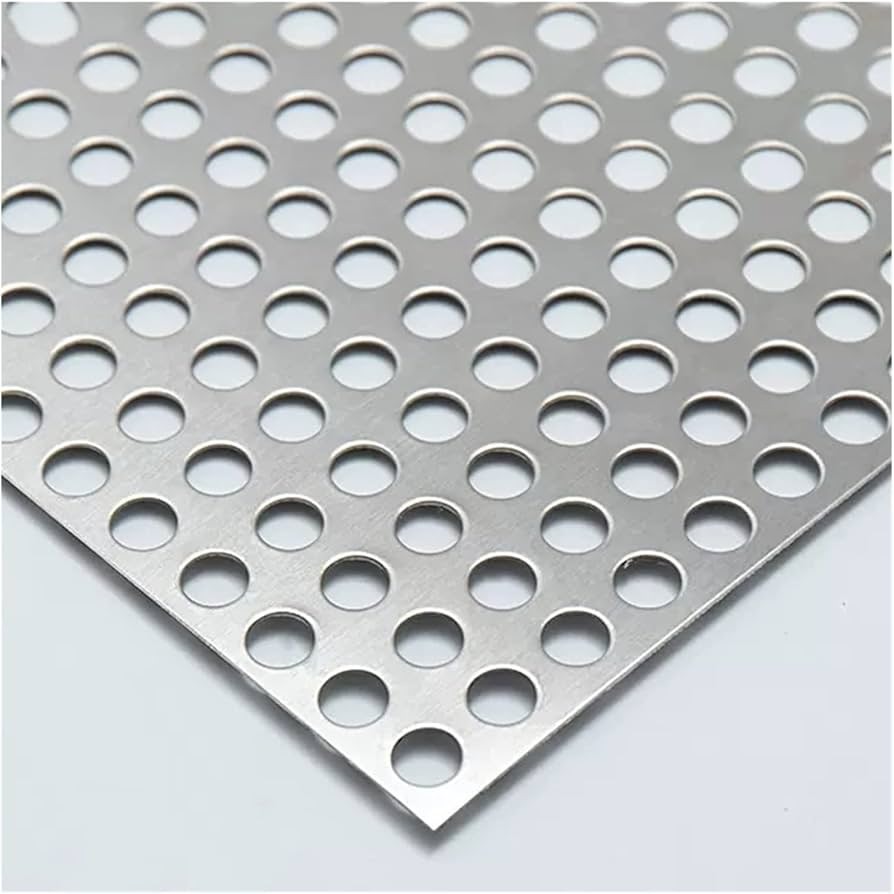

The "H" in the name stands for high carbon content, which helps improve strength and stability at elevated temperatures. It is highly resistant to intergranular corrosion, making it an excellent choice for applications involving corrosive media and elevated temperatures. Perforated sheets and plates are flat metal materials that have been punched or drilled with holes to create a desired pattern. The perforations in these sheets can vary in size, shape, and pattern, depending on the intended application. Perforated stainless steel sheets and plates are commonly used in architectural, industrial, and engineering applications where ventilation, filtration, or aesthetic appeal is important.

At Ferrobend, we follow a highly efficient and precise manufacturing process to produce top-quality Stainless Steel 321H perforated sheets and plates. Our advanced production methods ensure that each sheet or plate meets the required specifications, making it suitable for a wide range of industrial applications. The first step in the manufacturing process is selecting high-grade Stainless Steel 321H. The alloy is sourced from reputable suppliers to ensure it meets stringent quality standards. At Ferrobend, we only use premium raw materials to guarantee the final product’s durability and performance.

The next step is the perforation process, where we create holes in the stainless steel sheets and plates. At Ferrobend, we utilize advanced punching or laser-cutting technologies to create precise holes in various patterns. The perforation patterns can be tailored according to customer needs, whether they require round, square, or custom-shaped holes. The perforation process is done with great attention to detail, ensuring that the holes are evenly spaced and the edges are clean and smooth. The perforation process can also be adjusted for varying hole sizes and hole-to-material ratios.

Each batch of perforated Stainless Steel 321H sheets and plates undergoes a stringent quality control process to ensure that they meet industry standards. We test the products for mechanical properties, corrosion resistance, and dimensional accuracy. Our quality control team conducts inspections at every stage of the manufacturing process, from raw material selection to the final inspection, to ensure that the end product meets or exceeds customer expectations.

Stainless Steel 321H perforated sheets and plates are indispensable materials for industries requiring high strength, corrosion resistance, and temperature stability. Ferrobend’s expertise in the manufacturing of these materials ensures that you receive top-quality products that meet your needs. With our commitment to precision, quality, and customer satisfaction, we are your trusted partner for Stainless Steel 321H perforated sheets and plates.