Stainless Steel 321H

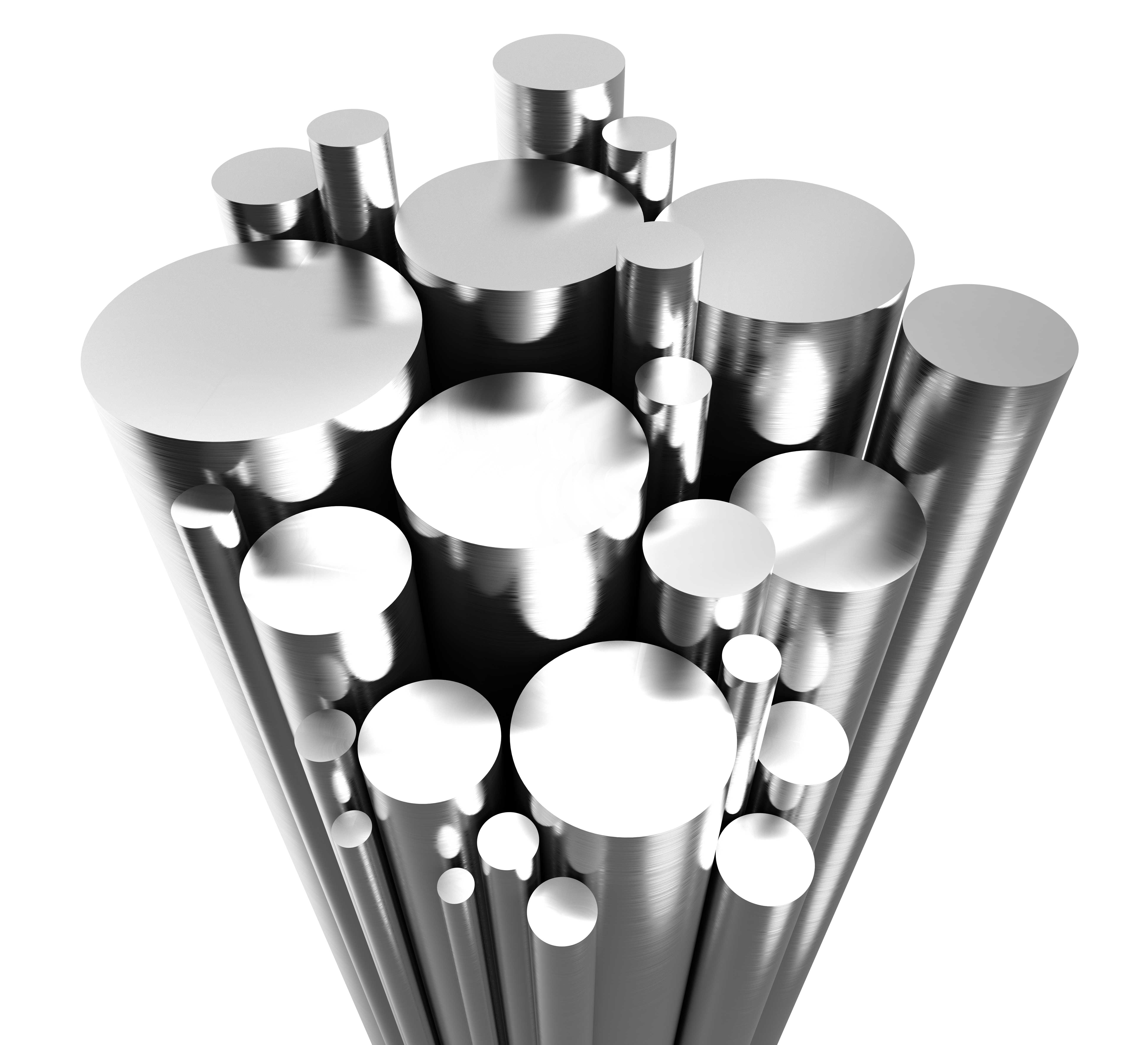

Stainless Steel 321H is a high-carbon, heat-resistant alloy that plays a vital role in numerous industrial applications due to its superior resistance to oxidation and corrosion at high temperatures. Known for its excellent welding properties and good mechanical strength, Stainless Steel 321H is a preferred material in industries such as aerospace, chemical processing, and power generation. In this article, we explore how Ferrobend, a leading manufacturer of stainless steel products, produces and supplies Stainless Steel 321H, and why it stands out as an optimal choice for various applications. Stainless Steel 321H is an austenitic stainless steel alloy containing high levels of chromium and nickel, combined with titanium for stabilization. The primary difference between 321 and 321H is the higher carbon content in 321H, which gives it enhanced high-temperature strength. This variant is particularly designed to resist carbide precipitation in the heat-affected zone, making it ideal for use in high-temperature environments where stress and thermal stability are paramount. Read More